An early Christmas present, the Excalibur Blade guard/ dust extraction by General Tools.

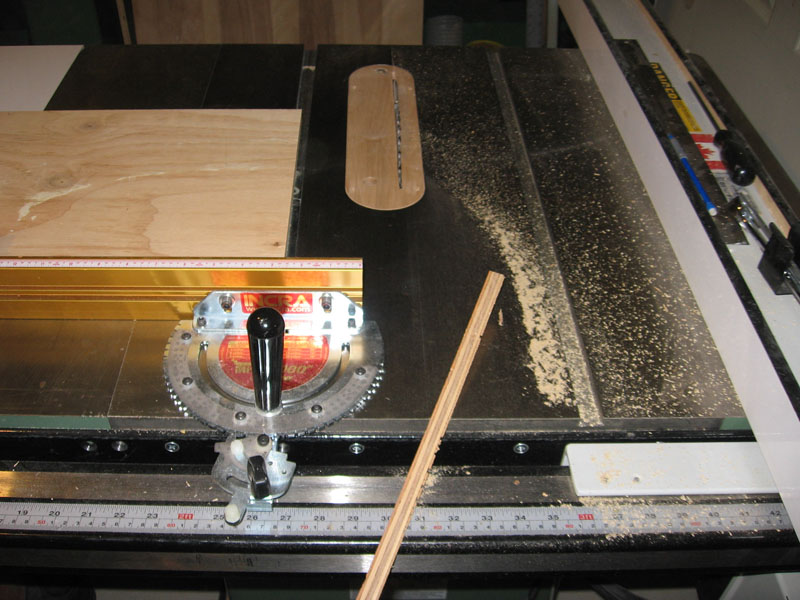

I installed this on my table saw yesterday and it works much better than I thought it would. There’s almost no dust when I’m cutting, the dust that does seem to escape is the larger particles that aren’t as harmful to my lungs. Here’s a shot of me making a few cuts without the guard or dust extraction turned on. You can’t see it but most of the dust is thrown towards me, behind me and mostly on the floor.

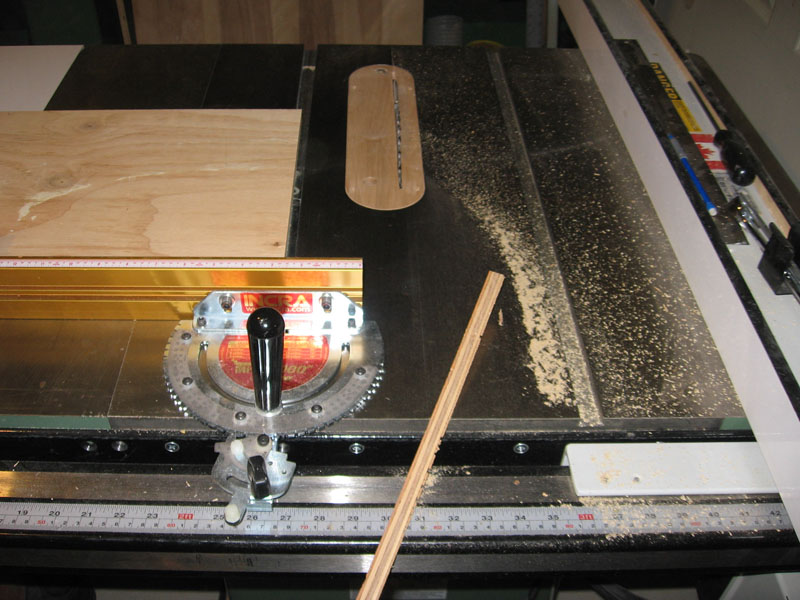

Here’s a shot with the guard over the blade and the dust collector turned on, it actually just pivots out of the way if you don’t need it.

There was no dust on me or on the floor that I could see. This is a huge improvement for the basement shot where dust is an important concern long term. I really should have gotten that years ago. Very recommended.